Call:

Ceramic Fire Fiber Blankets

Price 850 INR/ Piece

MOQ : 2000 Pieces

Ceramic Fire Fiber Blankets Trade Information

- Minimum Order Quantity

- 2000 Pieces

- Supply Ability

- 15000 Pieces Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- All India

About Ceramic Fire Fiber Blankets

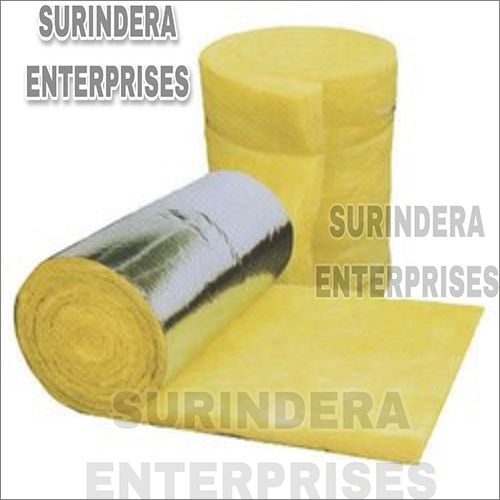

Ceramic Fire Fibre Blankets are typically used in high temperature duck and pipe insulation. These are formed from high quality Ceramic Fiber Bulk, using melt spinning or blowing process, the fiber being air-laid into a continuous mat and mechanically needled. They have low thermal conductivity, low shrinkage, resistance to chemical erosion(except hydrofluoric acid) and with high tensile strength. These ate completely inorganic, so there are no fumes when heating up. We offer our range of Ceramic Fire Fibre Blankets at most affordable prices.

Exceptional Thermal Resistance

These ceramic fiber blankets provide superior insulation for furnaces and kilns, effectively withstanding extremely high temperatures. Their unique material composition ensures heat retention, increases operational efficiency, and creates a safe barrier against fire. The silver-yellow color serves both for identification and for added visual safety around equipment.

Versatile Applications and Benefits

Not only do these blankets act as fire-proof protection, but their sound absorption properties also contribute to a quieter industrial environment. Flexible and easy to install, they are suitable for various high-heat industrial needs while providing energy savings and noise reduction. Our products are crafted to stand the test of intense operational demands in India and beyond.

FAQs of Ceramic Fire Fiber Blankets:

Q: How are ceramic fire fiber blankets used in high temperature furnaces and kilns?

A: Ceramic fire fiber blankets are installed as insulation linings within furnaces and kilns. Their high-temperature resistance allows them to protect equipment and personnel by limiting heat loss and containing extreme temperatures, thus enhancing energy efficiency and safety.Q: What benefits do silver-yellow ceramic fiber blankets offer for industrial applications?

A: These blankets deliver excellent fire-proofing and sound-absorbing performance, making them ideal for heavy industries. Their thermal insulation reduces energy consumption, while the distinctive silver-yellow color ensures easy identification and improves workplace safety.Q: When should ceramic fiber blankets be replaced or maintained in furnace operations?

A: Blankets should be inspected regularly for physical damage or wear. Replacement is recommended when there are signs of significant deterioration, loss of flexibility, or after prolonged exposure to harsh operating conditions. Routine checks optimize both thermal performance and safety.Q: Where can I source high-quality ceramic fire fiber blankets in India?

A: We are a reliable manufacturer, exporter, distributor, supplier, and wholesaler based in India, offering premium-grade ceramic fire fiber blankets suitable for demanding high-temperature industrial applications.Q: What is the process for installing a ceramic fiber blanket in a kiln or furnace?

A: Installation involves measuring and cutting the blanket to fit the application, then securing it in place using appropriate fasteners or adhesives. It can be applied as a lining or layered to achieve the desired level of insulation and fire protection.Q: How does the material composition of the blanket contribute to its fire-proof and sound-absorbing properties?

A: The ceramic fiber material is engineered with a high melting point and acoustic damping properties, enabling the blanket to resist extreme heat and absorb sound waves. This dual capability ensures both operational safety and a quieter work environment.Q: What makes your ceramic fire fiber blankets a preferred choice in the industry?

A: Our blankets are manufactured using high-purity ceramic fiber, ensuring outstanding durability, flexibility, and consistent performance. As trusted suppliers in India, we deliver solutions that meet stringent quality standards and cater to diverse industrial needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry