Industrial Fire Clay Mortar Available in all grades

Price 250 INR/ Bag

Industrial Fire Clay Mortar Available in all grades Trade Information

- Minimum Order Quantity

- 2000 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- All India

About Industrial Fire Clay Mortar Available in all grades

Industrial Fire Clay Mortar is mainly used as the joints and coating materials in building refractory bricks. It can adjust the tolerance of the fire clay bricks sizes and irregular shape, make the building tidy and balance the load. It also builds a strong and well-knit entity to resist external forces, prevent the damage by intrusion of gas and molten liquid. We offer quality range of Refractory Mortars used in building industrial furnace. It is accurately processed using high grade chemical compounds and latest technology at our advanced processing lab. Clientele can avail this Industrial Fire Clay Mortar at most competitive price.

Product details

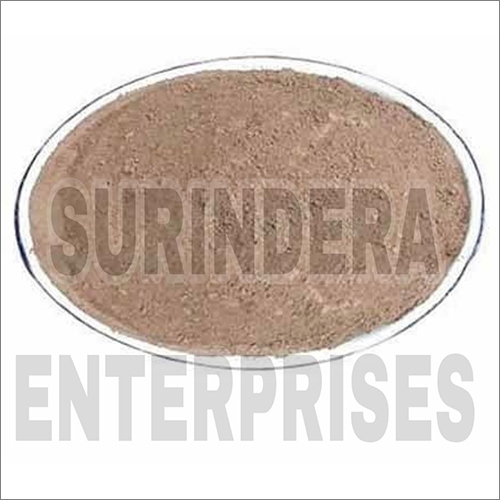

|

Form |

Granules |

|

Packaging Type |

Loose |

|

Material |

Clay |

|

Color |

Brown |

|

Usage/Application |

Brick Lining |

Premium Quality for Industrial Applications

Our fire clay mortar is formulated with selected high-grade chemical compounds, ensuring stable performance in demanding industrial environments. Each batch is produced with precision and advanced technology, guaranteeing consistency and superior bonding, suitable for brick lining and jointing refractory bricks.

Comprehensive Range and Versatile Uses

Available in all grades, this mortar addresses various industrial needs such as brick lining, joints, and protective coatings. It provides reliable service in steel plants, power stations, and foundries, ensuring seamless refractory construction and maintenance. We support supply chains as a dedicated distributor and exporter across India.

FAQs of Industrial Fire Clay Mortar Available in all grades:

Q: How is fire clay mortar applied for brick lining and joints in refractory work?

A: Fire clay mortar is applied between bricks or building blocks to create strong joints and seamless linings in refractory construction. After mixing the mortar with water to the required consistency, it is spread onto the surfaces to be joined or coated, ensuring proper adhesion and gap filling.Q: What benefits does this high-grade fire clay mortar offer during installation?

A: The mortar provides excellent bonding strength, high temperature resistance, and chemical stability. Its durable composition minimizes risk of cracks and ensures long-lasting refractory structures, making it suitable for use in furnaces, kilns, and industrial boilers.Q: When should fire clay mortar be used in building refractory brickwork?

A: Fire clay mortar should be used whenever reliable jointing, lining, or protective coating for high-temperature applications is required, especially in construction or repair of furnaces, kilns, and similar equipment exposed to thermal stress.Q: Where can this industrial fire clay mortar be sourced in India?

A: You can obtain this product nationwide from reputable distributors, exporters, manufacturers, suppliers, and wholesalers, ensuring swift delivery and technical support for your specific application needs.Q: What is the typical process for preparing and applying fire clay mortar?

A: The process generally involves mixing the mortar powder with clean water to the recommended consistency, applying it to clean, dust-free brick or block surfaces, and then placing the bricks to form strong, heat-resistant joints or coatings.Q: How does the use of fire clay mortar enhance the lifespan of refractory installations?

A: By ensuring robust adhesion, minimizing thermal gaps, and offering chemical durability, fire clay mortar protects against heat and corrosion, significantly extending the operational life of refractory brickwork.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Castable Category

WHYTHEAT K REFRACTORY CASTABLES

Price 900 INR / Bag

Minimum Order Quantity : 1000 Bags

Shape : Other, Not specified in the image

Application : Refractory Solution

Product Type : Other, Refractory Castables

Strength : Not specified in the image

FIRECRETTE SUPER SHREE CASTABLES

Price 600 INR / Bag

Minimum Order Quantity : 10000000 Bags

Shape : Powder

Application : FURNACE, BOILERS , REFRACTORY KILNS , KILNS , FIRE RESISTANT , HEAT RESISTANT

Product Type : Mineral Refractories

25kg Whytheat-K

Price 1 INR / Kilograms

Minimum Order Quantity : 2000 Pieces

Shape : Powder

Application : Chemical Industry, Dairy Plants, Electroplating Industry, Fertilizer Plant, Cement Industry, Ceramic Industry, Oil Refineries, Petrochemical Plants, Petroleum Industry, Textile Plants, Paper Industry, Tiles Industry

Product Type : Refractories

Strength : High

Alumina Refractory Castables

Price 1 INR / Kilograms

Minimum Order Quantity : 2000 Kilograms, ,

Shape : Powder

Application : Chemical Industry, Dairy Plants, Electroplating Industry, Fertilizer Plant, Cement Industry, Ceramic Industry, Oil Refineries, Petrochemical Plants, Petroleum Industry, Textile Plants, Paper Industry, Tiles Industry

Product Type : Refractories

Strength : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry